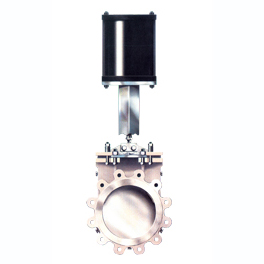

Recycle/drain knife gate valve

The recirculation/discharge knife gate valve is designed for solving the problem of recycling and excretion.

Many new and expensive valve configurations have been put into these applications for years, but the results have been modest.

Now the engineering solution provides a special structural knife gate valve that solves the valve problems that normally exist on these occasions.

The standard configuration

The knife gate valve is dedicated to solving specific problems in recirculation and excretion. Its configuration can minimize the impact of the following problems.

The seat is covered with a thick layer of special impact alloy layer on the inner diameter and surface to protect it.

The gate is made of extremely hard corrosion-resistant alloy.

Together they formed an effective, durable scissors, cutting wire, nails and other debris.

The physical damage (brake and seat) of the sealing surface: the sealing effect of steel wire, nails and other debris has been reduced to an unacceptable extent.

Blockage: steel wire, nails or other debris pile up at the bottom of the valve, causing the valve to be unable to completely shut off and leak.

Poor sealing performance: caused by surface damage, friction and high cycle condition.

The performance characteristics of

Excellent performance and convenient installation

Specially designed heavy open-cast stainless steel body can prevent the formation of small holes and prevent nails and wire from assembling here.

Besides being an effective shear, the hard gate can resist surface damage and maintain sealing performance.

Special wear - resistant seal and live - load sealing ring achieve high - cycle sealing performance.

The valve is simple, efficient and economical.